About us

Development, application of the latest technologies and innovative solutions

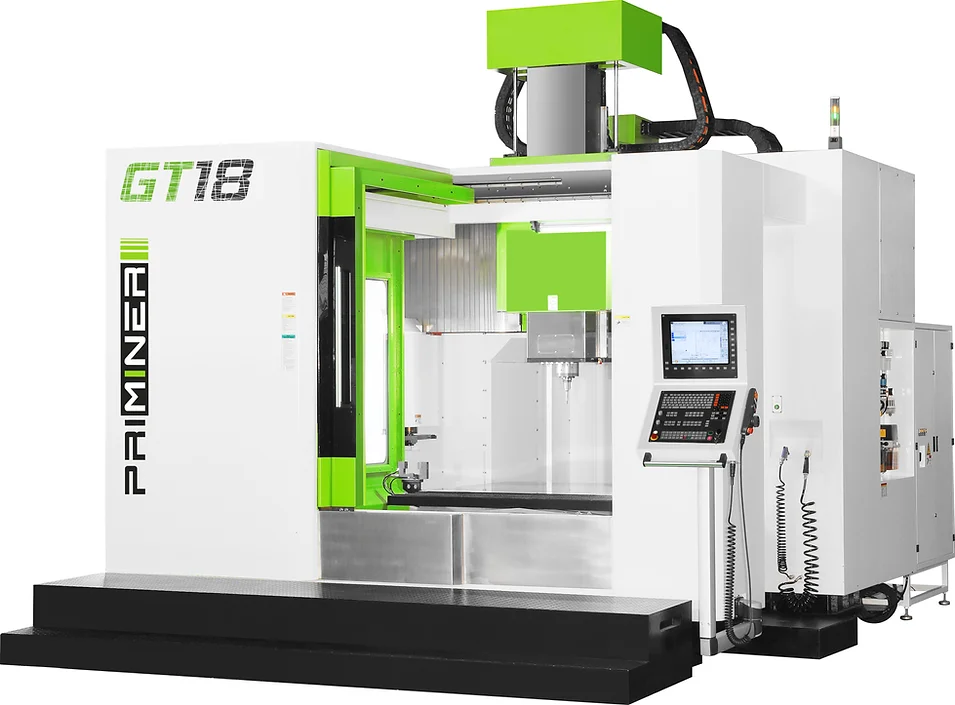

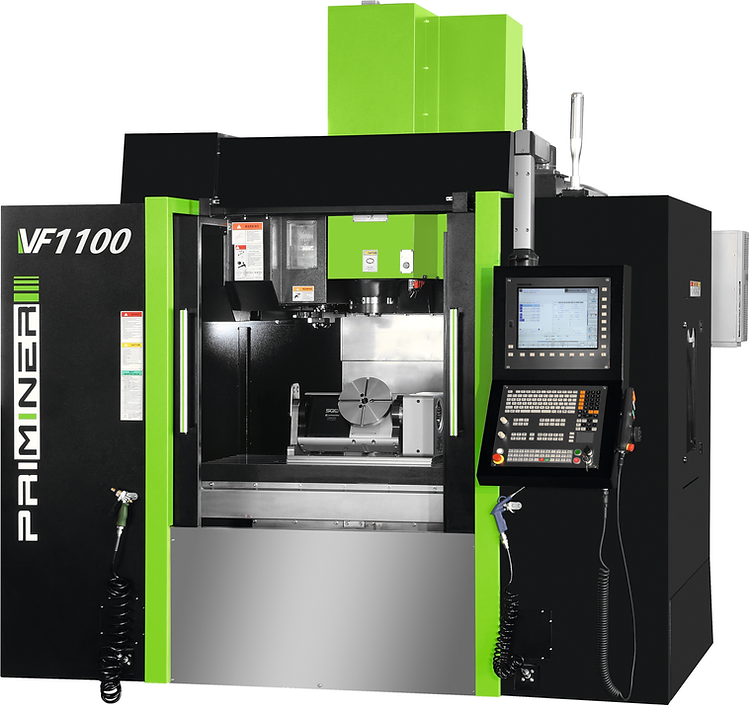

PRIMINER was founded in 2001 by a team of technical specialists with 20 years of experience in the machine tool industry. Today PRIMINER is one of the most dynamically developing manufacturers of machining centers in the world, whose quality is known on 5 continents. Our factory is located in Guangdong Province, China, Dongguan City, about 1 hour's drive from Shenzhen and Hong Kong ports. The total production area of the plant is 13,000 sq. m. PRIMINER has employees who speak 11 languages. Our international team of highly qualified employees is always ready to cooperate! Our collaborative culture is a mirror of our approach to work. The management of PRIMINER is always open to discuss new ideas and proposals. Our Priminer Uzbekistan team offers you service services (installation, commissioning, repair, diagnostics, etc.) throughout Central Asia and the CIS countries. The advantage of PRIMINER specialists is that the company is able to quickly respond to customer technical requests. Our specialists regularly undergo training from manufacturers in service maintenance.

We think and plan the future already now. A growing in-house R&D department with experienced engineers which develop our machine concepts are our warrantor that we are prepared for the upcoming trends of the machine tools business. We are listening to the market. Flexibility in the matter of CNC controllers is for us a must, here we only go with the market leaders. Without any compromise!