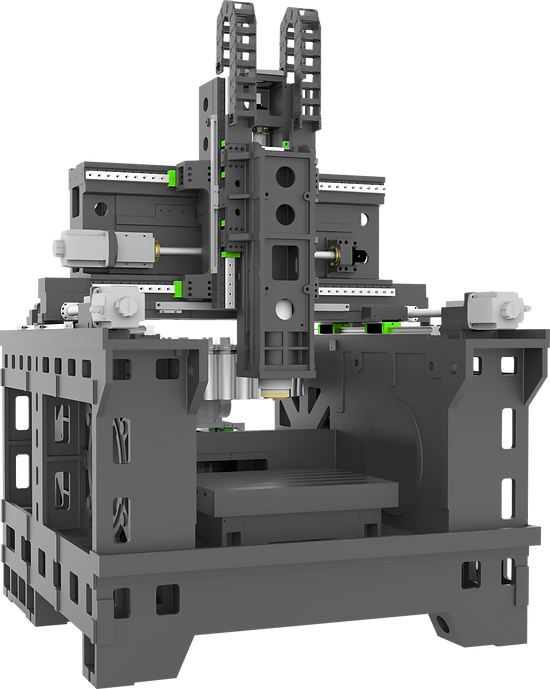

GT7

Description

• Best Choice for high speed cutting

• Gantry design with fixed worktable

• Dual drive system with two ballscrews on Y

axis to ensure the best dynamic.

• Compact design with mini. floor plan area

• Built-in spindle 36000 rpm, HSK E50

• Optional with graphite machining preparation

Standard configuration

- Full enclosed splash guard

- Built-in motor spindle HSK E50 36000 rpm

- 32 pockets tool changer

- Chain type chip conveyor

- Air-conditioned electrical cabinet

- High precision spindle water cooler

- Linear scales on X/Y/Z axis

- Rigid tapping

- Ethernet, CF card and USB interface

- Centralized automatic grease lubrication system

- Coolant system

- Air blast during cutting

- LED working lamp

- End of program light

- Electronic handwheel (MPG)

- Tool box

- Leveling bolts and blocks

- Coolant gun

- Air gun

- User Manual

- Chip conveyor (two screw conveyors and one chain conveyor)

Optional configuration

- Built-in spindle HSK A63 20000rpm, 32 pockets tool changer

- Built-in spindle HSK E32 40000rpm, 48 pockets tool changer

- Graphite Machining Preparation

- Oil mist collector

- Oil cooling through ballscrew

- CTS Coolant through spindle + ATS

- Oil skimmer

- Minimum Quantity Lubrication system

- Coolant Cooling system

- Workpiece probe

- Tool probe

- Extra 200GB SSD program memory